In a world where innovation drives progress, 3D printing solutions are revolutionizing industries. From manufacturing to healthcare, this technology is reshaping how products are designed and produced. With its ability to create complex structures quickly and cost-effectively, 3D printing is no longer just a novelty; it’s becoming a vital tool for businesses looking to stay competitive.

As companies explore the potential of additive manufacturing, they discover a range of applications that enhance creativity and efficiency. Whether it’s prototyping new designs or producing custom parts on-demand, 3D printing offers unparalleled flexibility. This article delves into the latest advancements in 3D printing solutions, highlighting their impact and the future they promise.

Table of Contents

ToggleOverview of D Printing Solutions

D printing solutions encompass a range of technologies that utilize additive manufacturing processes to create three-dimensional objects. These solutions provide significant advantages across diverse sectors, enhancing capabilities in product design and development.

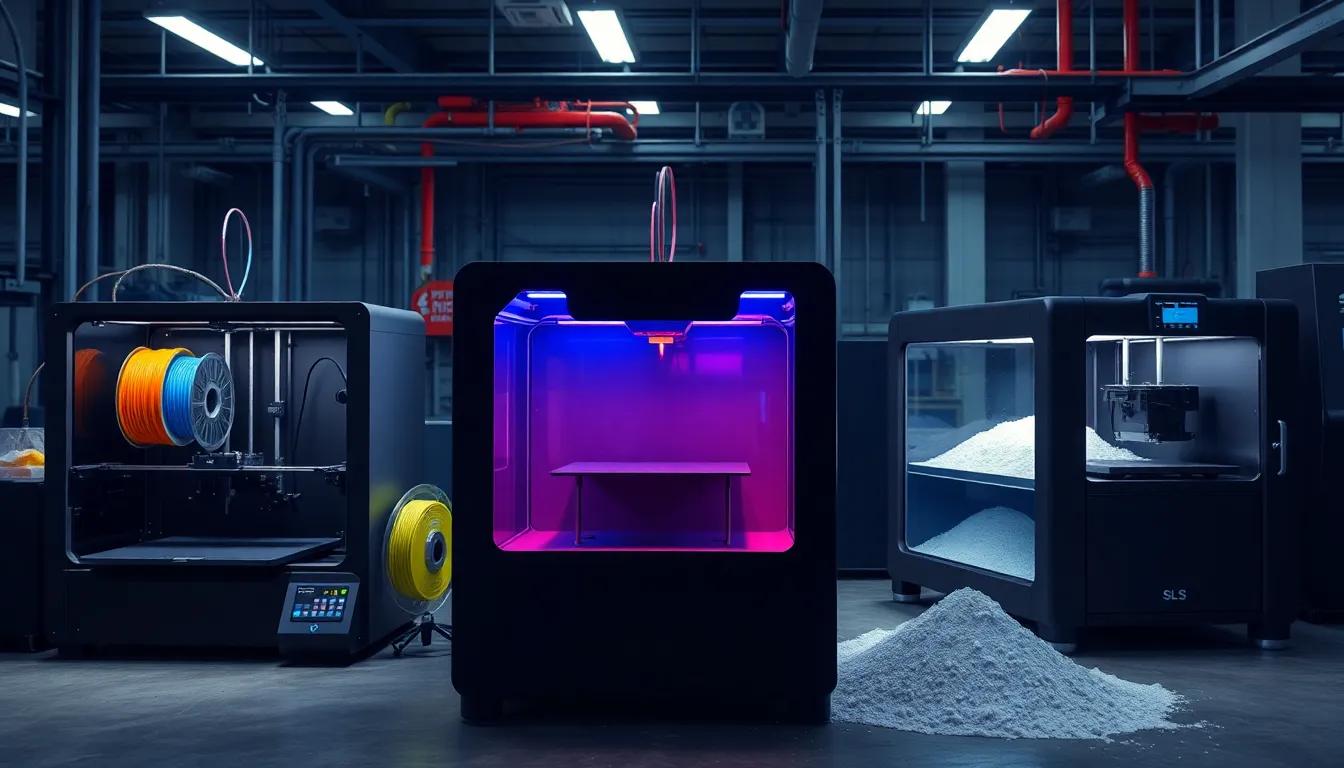

D printing technologies can include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and others. Each technology offers unique benefits suited for specific applications.

Key Applications of D Printing Solutions:

- Manufacturing: D printing streamlines production processes by reducing waste and creating custom parts quickly.

- Healthcare: D printing produces patient-specific medical devices, prosthetics, and anatomical models for surgical planning.

- Aerospace: D printing enables the creation of lightweight components, improving fuel efficiency and performance.

- Automotive: D printing accelerates prototyping and part production, reducing time to market for new vehicles.

Recent Advancements:

- Materials Development: Innovations in materials, such as bio-compatible plastics and metals, expand the range of applications.

- Speed Improvements: Enhanced printing speeds lead to faster turnaround times for prototypes and end-use products.

- Software Integration: Advanced software platforms streamline the design process, allowing for easier modifications and optimizations.

D printing solutions are revolutionizing traditional manufacturing, fostering innovation and efficiency. As advancements continue, the potential for this technology grows, enabling industries to explore new possibilities and solutions.

Types of D Printing Technologies

Different 3D printing technologies serve various purposes across industries, each offering distinct advantages. Here are the primary types of 3D printing technologies:

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) uses thermoplastic filaments to create objects layer by layer. It heats and extrudes the filament through a nozzle, allowing for precise shaping. FDM is cost-effective and widely used for prototyping and production of functional parts. Common applications include manufacturing prototypes, production tooling, and customizable consumer products, primarily due to its ease of use and material availability.

Stereolithography (SLA)

Stereolithography (SLA) employs a UV laser to cure liquid resin into hardened plastic. The laser selectively solidifies the resin into the desired shapes, layer by layer. SLA produces highly detailed and smooth surfaces, making it suitable for industries requiring precision, such as jewelry, dental devices, and complex prototypes. This technology excels in creating intricate geometries while maintaining a high level of accuracy.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) uses a powerful laser to fuse powdered materials, including plastics and metals. The laser selectively sinters the powdered material, forming solid structures layer by layer. SLS is known for producing strong, functional parts, ideal for end-use applications and complex geometries. Industries such as aerospace and automotive often utilize SLS for lightweight components and custom production due to its durability and design flexibility.

Applications of D Printing Solutions

3D printing solutions offer diverse applications across multiple industries, significantly enhancing production capabilities and innovation. The following subsections provide detailed insights into prominent applications: prototyping, manufacturing, and medical fields.

Prototyping

Prototyping benefits immensely from 3D printing solutions. Designers and engineers use additive manufacturing to create rapid prototypes, enabling quick iterations and adjustments without extensive lead times. Fused Deposition Modeling (FDM) excels in producing functional prototypes cost-effectively, allowing teams to test designs and materials efficiently. Stereolithography (SLA) provides high-resolution prototypes, essential for industries requiring detailed visual feedback. Rapid prototyping reduces development times by as much as 50%, fostering innovation and collaboration.

Manufacturing

3D printing solutions significantly transform manufacturing processes by streamlining production and minimizing waste. Selective Laser Sintering (SLS) facilitates the creation of complex geometries that traditional manufacturing methods cannot achieve. With on-demand production capabilities, companies produce parts as needed, reducing inventory costs. Industries utilize additive manufacturing to create lightweight and durable components, particularly in aerospace and automotive sectors. Manufacturing efficiency improves as companies report reductions in production costs by up to 70%.

Medical

Medical applications of 3D printing solutions are revolutionary. Customized implants and prosthetics are tailored to individual patients, enhancing comfort and fit. Bioprinting, a specialized form of 3D printing, allows for the creation of tissue and organ structures, paving the way for advanced translational medicine. Furthermore, surgical models produced using additive manufacturing offer precise anatomy replication, improving surgical planning and outcomes. Healthcare organizations experience improved patient care and reduced surgical times as a direct result of adopting these innovative technologies.

Advantages of D Printing Solutions

D printing solutions offer numerous advantages that significantly benefit various industries.

- Cost-efficiency: D printing reduces manufacturing costs by minimizing material waste and decreasing production lead times. It allows for the creation of intricate designs without the expense of traditional tooling, leading to potential savings of up to 70%.

- Rapid prototyping: D printing facilitates faster iteration of designs. It enables quick adjustments and validation of concepts, cutting development times by as much as 50%. This speed and flexibility empower designers to innovate effectively.

- Customization: D printing supports the production of highly customized products tailored to specific needs. Companies can manufacture unique items, including patient-specific medical devices, with precision and efficiency.

- Complex geometries: D printing allows the creation of complex structures that traditional manufacturing cannot achieve. It designs lightweight, optimized parts, aiding industries like aerospace and automotive in improving performance while maintaining structural integrity.

- On-demand production: D printing enables on-demand manufacturing, reducing the need for large inventory stocks. This flexibility can lead to faster responses to market changes, allowing businesses to adapt quickly.

- Material diversity: D printing supports a wide range of materials, including plastics, metals, and bio-materials. This versatility allows for innovative applications across varied fields, enhancing product functionality and performance.

- Sustainability: D printing promotes sustainable practices by reducing waste and utilizing materials more efficiently. It also fosters recycling initiatives, contributing to eco-friendly manufacturing processes.

- Global accessibility: D printing makes manufacturing more accessible worldwide. It empowers small businesses and startups to produce high-quality products without substantial investment in equipment or facilities.

D printing solutions present transformative benefits that enhance creativity, efficiency, and sustainability across industries.

Challenges and Limitations

3D printing solutions face several challenges and limitations that can affect their broader adoption.

- Material Constraints: The range of available materials, while expanding, still lacks certain properties. Materials like metals, ceramics, and composites can be costly or require specialized processes for effective printing.

- Surface Quality: The surface finish of 3D printed parts often requires post-processing. Smoothing techniques, such as sanding or polishing, increase production time and costs.

- Speed of Production: Although faster than traditional methods for certain applications, 3D printing can still be slower for large-scale production. Many industrial applications require higher production rates that additive manufacturing struggles to meet.

- Size Limitations: Printer bed sizes restrict the dimensions of printed objects. Larger items may need to be printed in segments, complicating assembly and potentially compromising structural integrity.

- Design Optimization: Not all designs translate well to 3D printing. Complex geometries may lead to difficulties during the printing process or result in parts that lack the desired strength or durability.

- Regulatory and Certification Issues: Industries like aerospace and healthcare require strict adherence to regulations. Certification processes for 3D printed parts are often lengthy, hindering their quick adoption.

- Technical Expertise: Operating and maintaining 3D printers requires skilled personnel. A shortage of open-source resources and training can limit the effective use of this technology.

- Cost of Entry: While prices for 3D printers are declining, initial investment and ongoing material costs can still be prohibitive for small businesses or startups.

Identifying and addressing these challenges helps maximize the effectiveness of 3D printing solutions across various industries.

3D printing solutions are reshaping industries by offering unprecedented flexibility and efficiency. As businesses continue to embrace this technology, they unlock new avenues for innovation and creativity. The ability to produce customized products quickly and cost-effectively positions companies to meet evolving market demands.

While challenges remain, ongoing advancements in materials and techniques promise to enhance the capabilities of 3D printing. As organizations navigate these obstacles, the potential for transformative applications across manufacturing, healthcare, and beyond becomes increasingly clear. The future of 3D printing holds exciting possibilities, paving the way for a more sustainable and innovative manufacturing landscape.